The well-founded training of our employees in technology and engineering, as well as many years of experience in the food industry, combined with short internal communication channels and close customer contact, ensure that we can effectively assist you in solving your tasks and problems with individually tailored solutions.

Personal customer contact, short response times, unbureaucratic action as well as cost- and time-efficient order processing are not just buzzwords for us, but an integral part of our daily work.

We ensure the long-term satisfaction of our customers with intensive support and high-quality work. In short: Our customers’ concerns are our top priority.

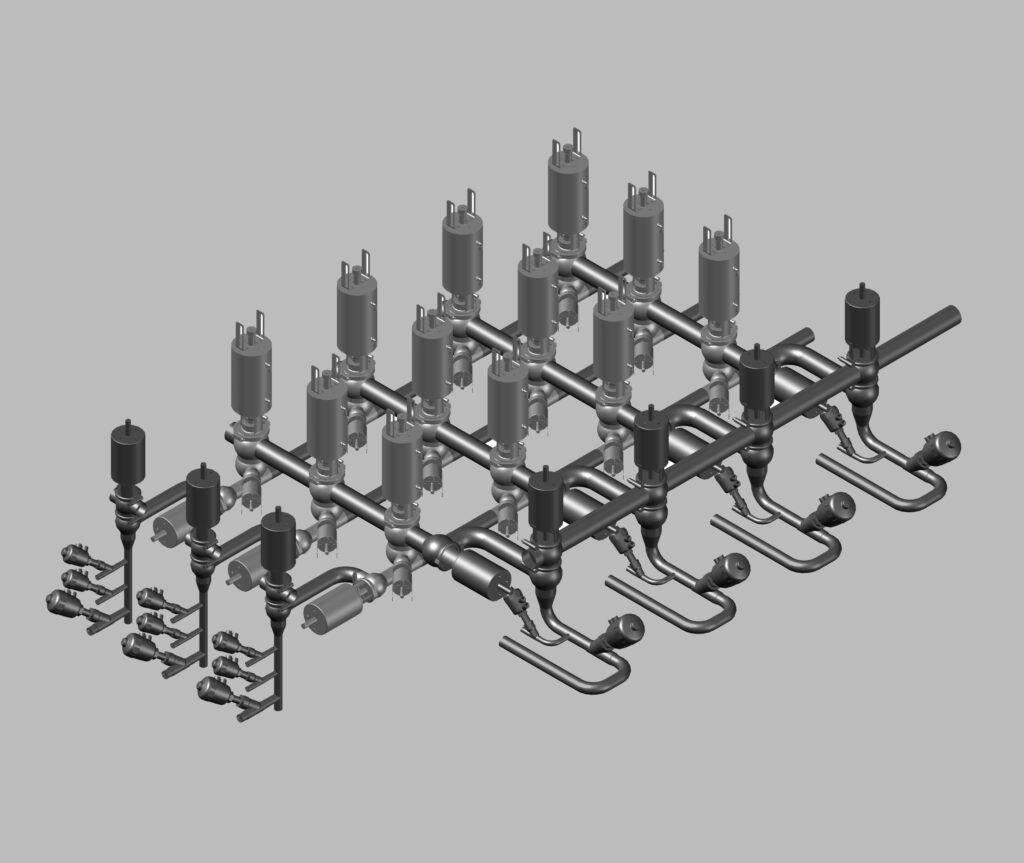

We support you in terms of concept development, planning and implementation for:

Project engineers with many years of experience in food technology are available to you for preliminary planning, detailed planning and project planning:

During the execution phase of a project, we support you with well-coordinated and experienced staff from our technical office. As our customer, you have a personal contact person for all matters – from the first meeting to the completion of commissioning. Your personal contact is an experienced project engineer who has access to your project-relevant data at all times and coordinates the following core tasks:

For the implementation, we rely on assemblers, senior assemblers and master assemblers with years of experience and routine in stainless steel plant construction. Our assembly personnel are distinguished by the careful working methods required in the food industry and especially in hygiene areas.

Compliance with factory standards is just as much a matter of course as the execution of assembly work in accordance with the latest state of the art. In addition, our assembly personnel regularly take part in further training events (e.g. DVS, TÜV welding examinations and general further training in TIG welding).

The commissioning of a newly erected or extended process plant is carried out by one of our engineers in close cooperation with the plant programmer and your specialist personnel and includes the following services:

We see ourselves not only as a plant manufacturer, but also as a service provider for you and your plants during the operating and utilisation phase.

MHG supports you during the utilisation phase of your plant by:

MHG Prozesstechnik GmbH

Bruckmühler Str. 23

D-83052 Bruckmühl